FORMTEK/LOCKFORMER/ENGEL

Q. Why do HVAC Contractors buy TDC/TDF flanging machines?

A. Really, the answer is quite simple, these machines roll the 35mm standard flange onto existing duct in about 6 seconds per length.

The alternative method is to buy expensive knock on flange, approximately $2.75 per metre in 5 metre lengths so when you are trying to manufacture a piece of duct you take the flange off the shelf, cut 4 pieces, deburr it, fit it with expensive corners, place on the end of the raw edge, and either tech screw or spotweld and seal.

With TDC/TDF you simply notch your sheet, roll of the flange, bend up the duct and clip in 4 corners at $1.20 all up. The TDC/TDF method will save you approx. $40 per joint. Eliminates the necessity to stock knock on flange, it saves your cash flow as well as labour savings. The TDC/TDF method is really a no brainer. Any serious Duct Manufacturer can not afford to not use either TDC or TDF.

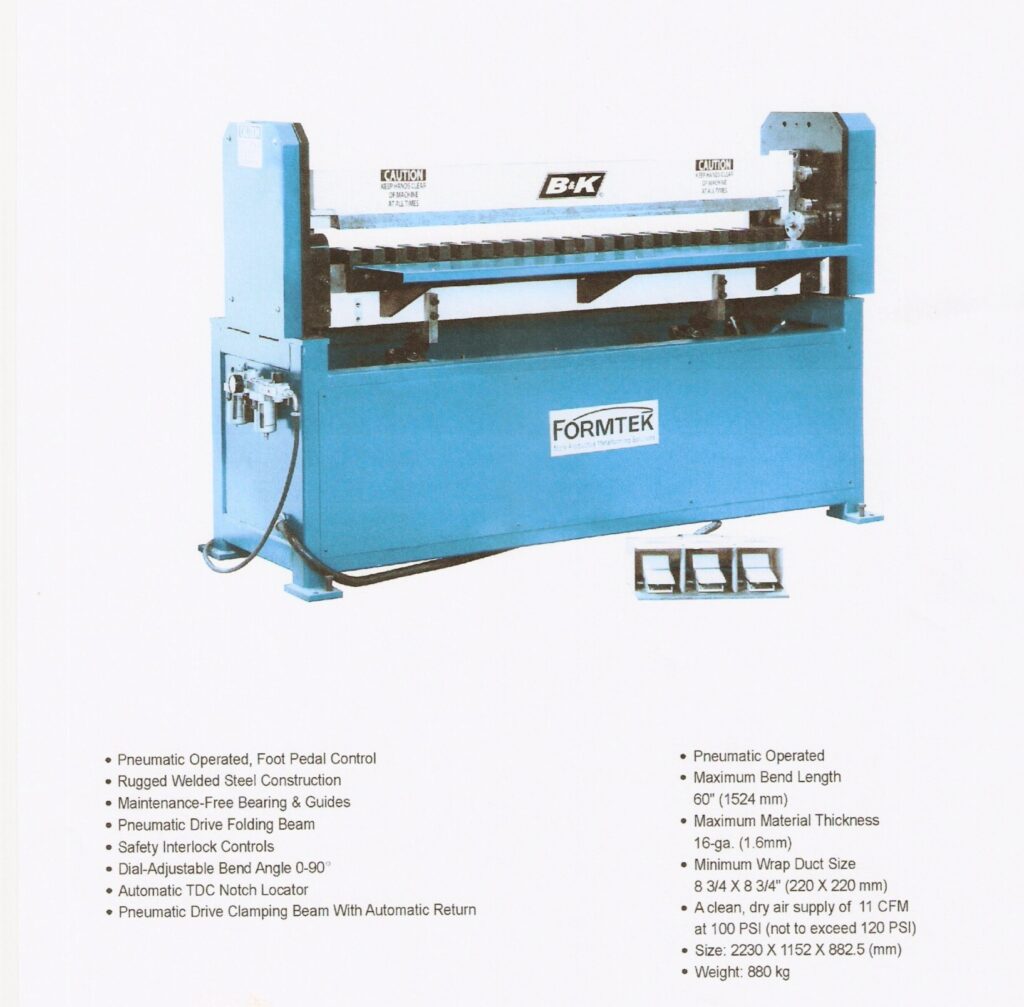

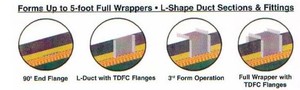

Use the TDC/TDF method with a beading machine for strengthening ribs in lieu of time consuming cross braking for a better looking piece of duct. Fold the duct in L Shape, C Shape, or Wrap utilising the Kleen TDC/TDF Wrap Brake. You’ll be amazed at the savings your business can make.

LOCKFORMER TDC™ ROLL FORMING SYSTEMS

TDC Flange Profile TDC Clip

The TDCV machine is tooled with 35mm TDC flange rolls on one outboard position. TDC clip rolls are supplied on the other outboard roll position.

SPECIFICATIONS:

- TDCV 12 station machine

- One set of TDC Rolls included standard

- One short part fitting carriage and guide rail

- 7.5 HP 1450 RPM 3 phase motor

- Speed 14 meters per minute approx.

- Approximate weight 1400kg

TDF Flange Profile TDF Clip

TheTDF machine is tooled with 35mm TDF flange rolls on one outboard position. TDF clip rolls are supplied on the other outboard roll position.

NOTE: STANDARD TDC CORNERS ARE USED WITH BOTH TDC AND TDF FLANGES.

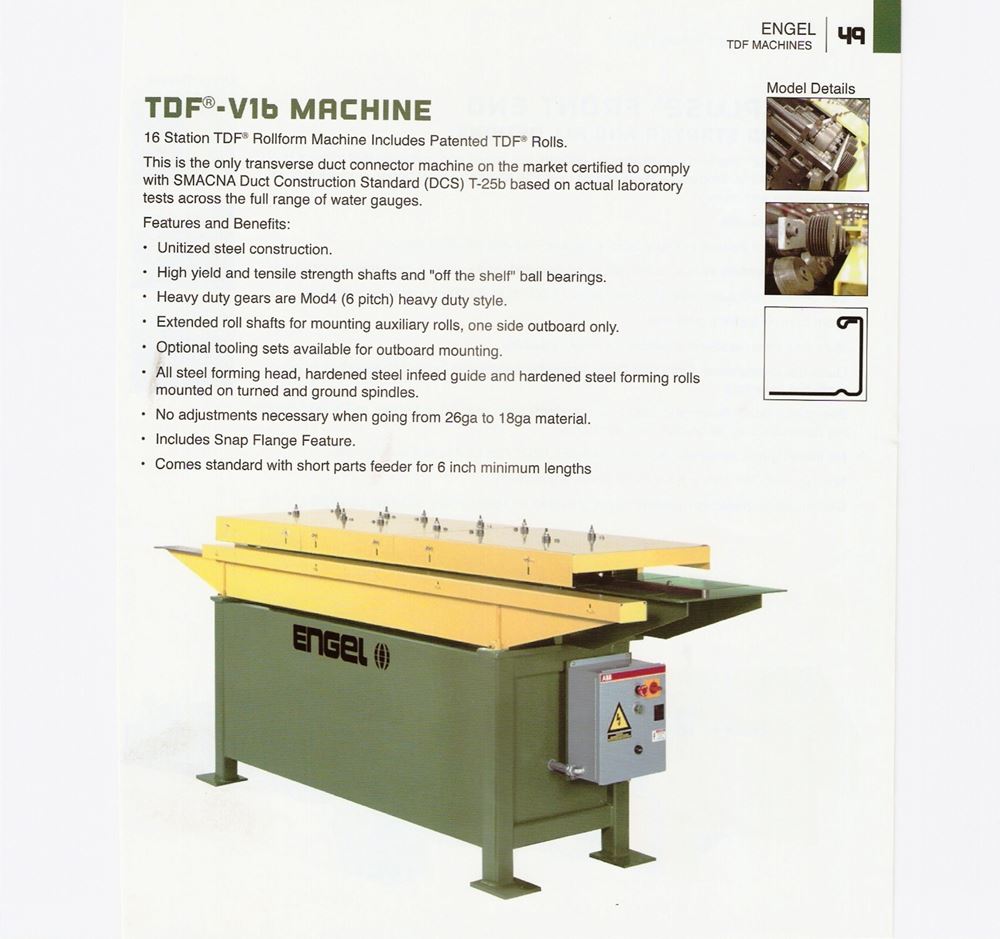

ENGEL TDF™ SYSTEMS

This machine has stood the test of time and is a robustly manufactured 16 station rollforming machine. It will form up to 16 gauge material with a standard 35mm TDF profile rolls.

Optional rollsets to form the TDF clip, or 16 gauge Pittsburgh fitted on outboard stations are also available.