New Products

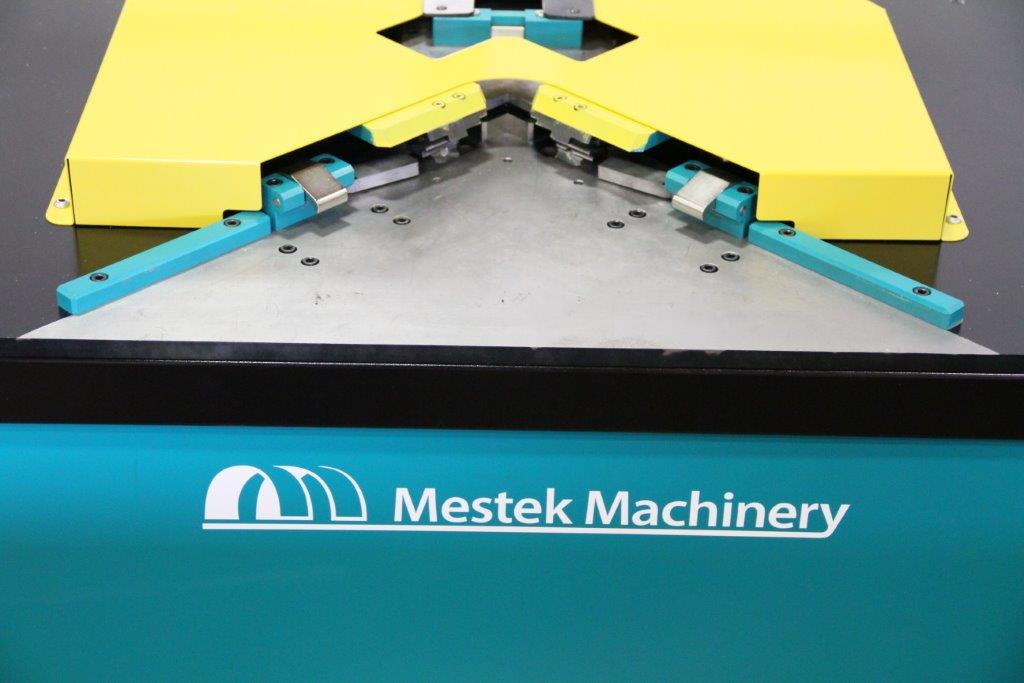

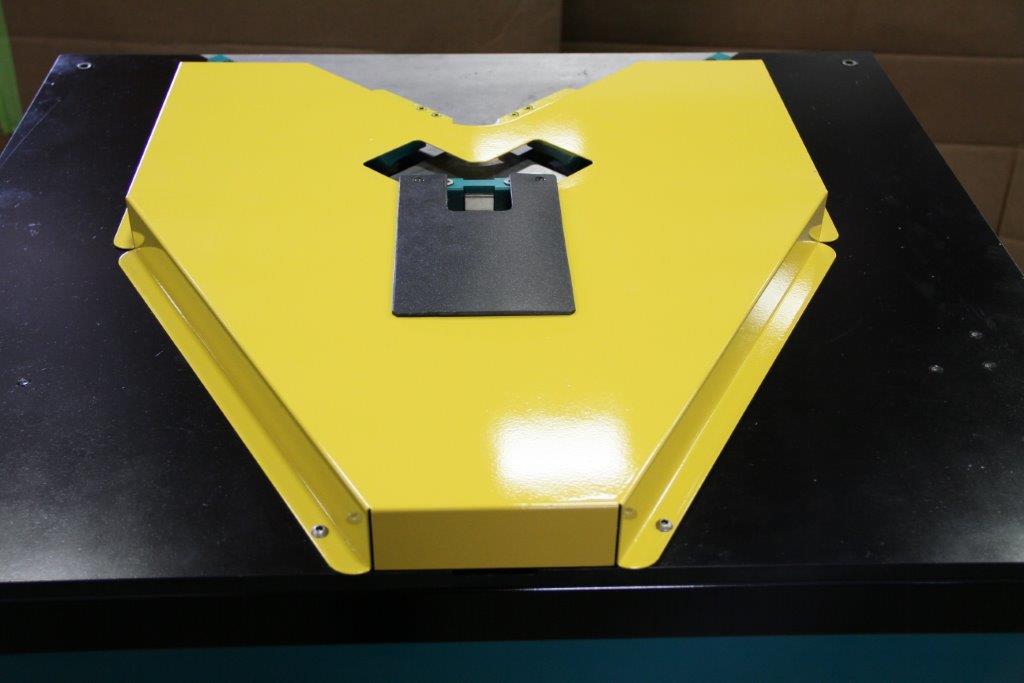

CORNERMATIC PLUS

The Cornermatic + Plus automatically inserts and crimps TDC/TDF corners in seconds. In can inset Eight(8) corners in approixmately 20 seconds in any gauge.

- Push the ductowrk or fitting into the flange guides and the machine automatically does the rest.

- Corners are inserted square and fully crimped

- Note necessary to change the crimping adjustment using different gauges.

- Quick loading box holds 80 cornser.

- Corners are shipped pre-sorted in a cardboard sleeve for direct loading to the magazine.

- Will handle any fitting built to SMACNA standards.

- Willl hadnle difficult inside angles an dtight square throats as well as off size fittings.

- 415v, 3 phase, 10amp power, air at 80psi.

Cornermatic II Whisperloc Combo.

The CORNERMATIC II® ~ WHISPER-LOC® COMBO is a unique, innovative machine that not only inserts and crimps corners into both ends of ductwork but closes longitudinal Pittsburgh seams on the same ductwork when required. This design allows the operator to accomplish both corner insertion and seam closing on one machine without having to handle the ductwork between processes.

The corner insertion is a pneumatically operated process that rapidly and automatically inserts and crimps corners into both ends of ductwork that uses the TDC® or TDF® method of joining. This unit automatically places a corner piece into a corner on each end of the duct and crimps them securely and permanently into place.

The seam closing is powered by an electric motor and gearbox using a Variable Frequency Drive. It will accommodate duct with various end joining methods. It will close the Pittsburgh seam as well as insert corners on any ductwork that uses the duct flanges conforming to T25-a or T25-b under the Duct Construction Standards. It will also close the Pittsburgh seam only on ductwork that uses the raw edge or slip and drive method.

Corners for this automation are quickly loaded into the magazines from the shipping cartons. The corners come oriented and stacked in the carton for quick and easy loading. The CORNERMATIC II® ~ WHISPER-LOC® COMBO is capable of utilizing either standard boxed corners or pre-packaged disposable cardboard sleeves with a simple quick magazine changeover. The standard boxed corner magazines hold 90 corners and the “new cardboard sleeved corners” come loaded with 80 corners per sleeve. The process is virtually noiseless.

Power: 415 Volt, 3 phase, 10amp, power, air at 80psi

Size: 30-1/2″ x 34″ x 96 1/8″ (775 x 850 x 2442 mm)

Weight: 1800 lbs. (818 kg)

Single Head Corner Caddy

This machine is for the insertion automatically of TDC and TDF Corners. The machine is lightweight and portable for easy transfer to various workstations in your factory. It eliminates your workers bending and hammering corners in, thus greatly reducing the noise. The corners are loaded in the raked back magazine which carries 175 corners which automatically feed one after another. For these machines to work effectively you should buy patented Cornermatic TDC and TDF corners.

For 18 – 26 gauge material, single phase 240v, 90psi air required.

Machine size 1000mm x 1000mm x 1100mm high, 130kgs.

Dual Head Cornermatic

Automated Ductwork Corner Insertion and Fastening System

This versatile machine features dual heads for corner insertion. The bottom station is fixed and the top station is power adjusted to suit variable duct lengths. This machine is specifically designed to install patented TDC/TDF cornermatic corners. The machine allows you to insert 8 corners in approximately 15-20 seconds with no need for end to end duct, simply rotate corner to corner as the machine inserts corners to both ends simultaneously.

The machine has a magazine top and bottom which holds 170 corners each. The insertion of corners using the dual head Cornermatic saves approximately 3-6 minutes compared to the old hand insertion per duct length. To operate you simply push the duct at floor level into the cornermatic guides and the machine automatically inserts and crimps the corners at both ends.

For fittings the top station can be isolated and only the bottom station utilized.

Ideally the machine should be mounted in a pit approximately 600mm sqaure and 500mm deep to ensure the bottom corner station is level with the floor.

Electrical: Single phase 240v 50hz, air 80-100psi.

Machine size: 616mm x 616mm x 2946mm, Weight 450kgs

Cornermatic Corners

TDC/TDF

- Adaptability – Handy for every job. Cornermatic’s new rigid corners can be easily installed by machine or by hand.

- Easy Loading – Cornermatic corners are stacked and packed ready for easy loading into cornermatic machine.

- Quality Workmanship – Corner facilitate jam-free installations into ducting sections.

- Durability – Added strength and rigidity to duct sections. Maintains quality from packing to installation.

- Cost Effective – Quantity discounts apply.